Portion Common Assessments For Automobile ICs Not Fantastic Adequate

Part Regular Testing (PAT) has extensive been utilised in automotive. For some semiconductor systems it stays practical, although for other people it is no for a longer period superior adequate.

Automakers are bracing for chips produced at state-of-the-art approach nodes with substantially trepidation. Limited manage of their supply chains and a reliance on mature electronic procedures so far have enabled them to enhance digital factors in a nicely-managed fashion. But as the number of chips made use of in vehicles raises from hundreds nowadays to thousands in the potential, and as the degree of automation proceeds to grow, they are going through a raft of alterations for which there is minimal precedence.

This involves almost everything from logic chips developed applying the most sophisticated course of action geometries, to new packaging technologies that needs ball grid arrays to exchange wire bonding. And while automakers are demanding zero problems, many others are nervous about automobile technique failures stemming from aspect typical screening, which may not be adequate for all of the chips used in a auto.

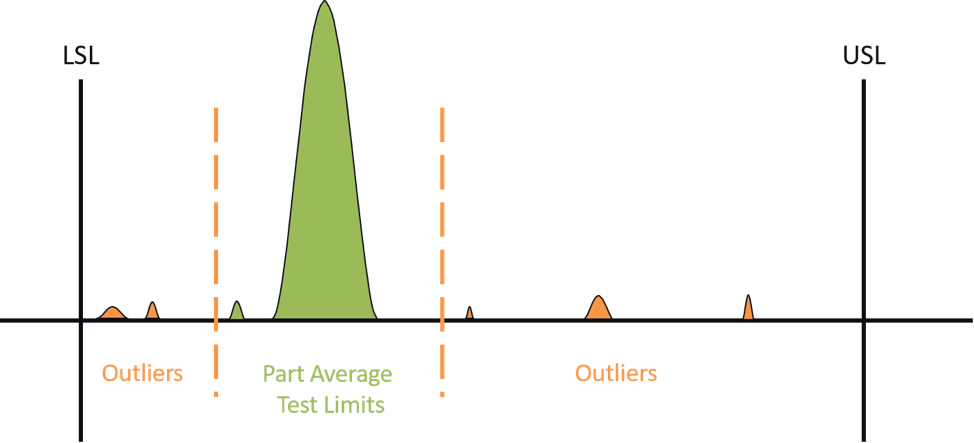

PAT utilizes statistical management limits all through production to improve equally generate and stop-of-the-line good quality. In the vehicle field, engineers have been implementing this principle to electrical take a look at measurements business for practically 30 many years.

“History has demonstrated that areas with irregular features drastically add to quality and trustworthiness troubles,” states the PAT suggestions from the Automotive Electronics Council. “Use of this procedure will also flag procedure shifts and deliver a source of speedy responses that really should prevent top quality mishaps.”

At least that has worked with mechanical methods and older-node products, and semiconductor information analytics and ATE distributors have been assisting their prospects in applying PAT. But that extended suffices for AI systems in vehicles, which require the most advanced nodes for actual-time decision-earning in vehicles. As a outcome, product and reliability engineers are migrating to far more refined outlier detection methods, and amplified protection for inspection and examination.

Recently, inline meteorology organizations, this sort of as KLA and SVXR, have formulated faster scanning technologies that now enables 100% sampling of wafers and offers. Consequently, like PAT, population figures now can be applied to graphic analysis.

“Automotive shoppers have a extensive legacy of focusing on good quality to catch the attention of and keep clients, mentioned Jay Rathert, senior director of strategic collaborations at KLA. “Their solution is really analytical and proactive, and they are bringing that similar rigor to semiconductors. The the greater part of automotive chips in cars currently are from experienced procedures. The new problem is running the lots of intricate things influencing quality as they combine chopping edge ADAS chips designed on superior layout principles.”

Automotive silicon systems and exam demands

When the drumbeat in automotive sector has been “zero defects,” finding there is turning into extra problematic. Engineers need to look at a wide vary of semiconductor equipment and their associated take a look at expenses when picking an over-all exam technique. Zero flaws is highly-priced, and financial gain margins are limited.

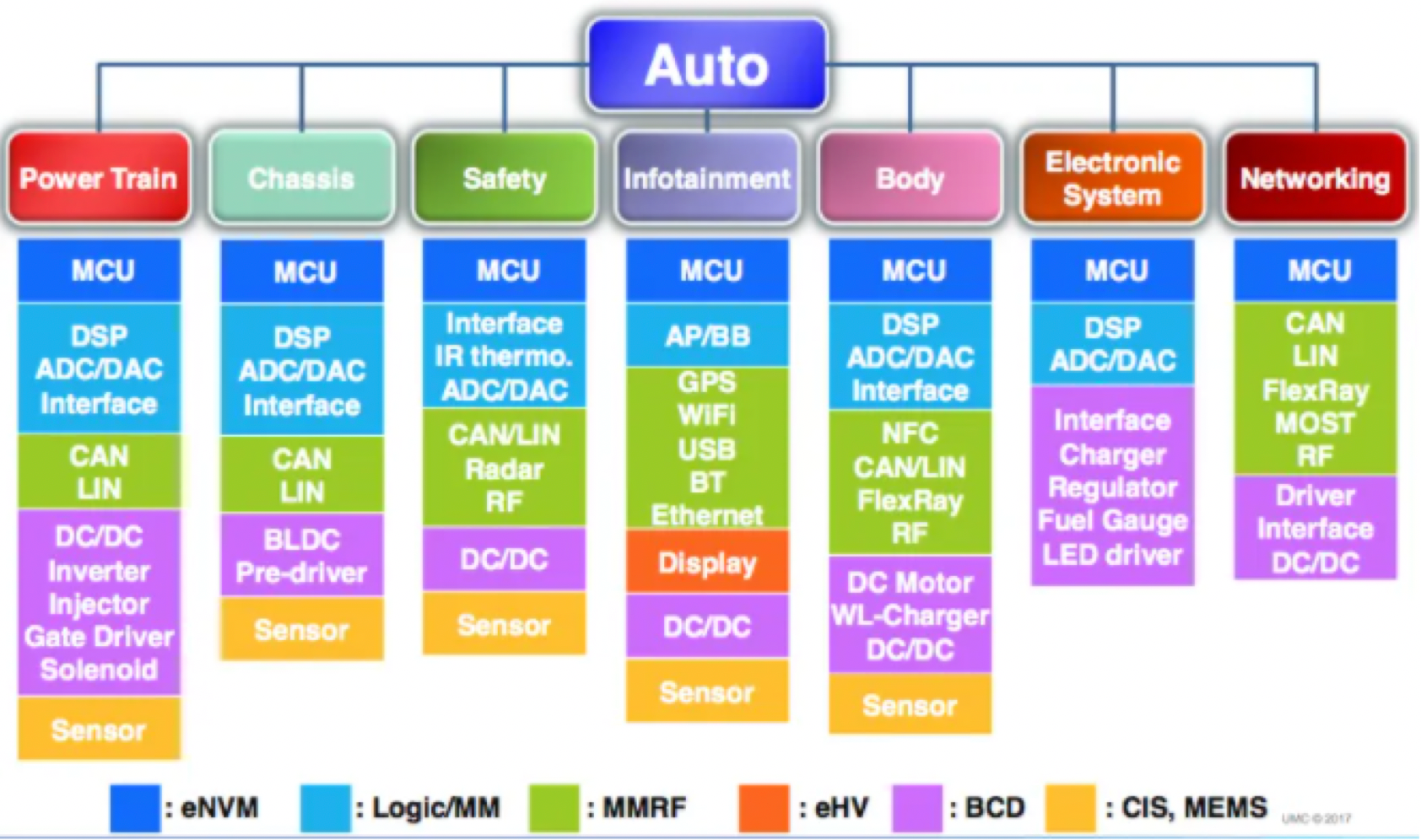

Cars consist of a huge range of semiconductor technologies. These technologies have unique important proportions, failure mechanisms, and process variability. Check prerequisites will differ, relying upon any of these variables. A substantial-electrical power MOSFET for power applications will have vastly various take a look at requires than a advanced neural network, for instance.

Fig. 1: Diversified silicon technologies identified in automotive, such as eNVM, logic major memory (Logic/MM), mix method RF (MMRF), embedded significant voltage (eHV), bipolar CMOS-DMOS (BCD) and CMOS image sensor (CIS)/MEMS. Resource: UMC

Some of these variations are evolutionary. Alternatively than a purely mechanical actuator, for case in point, there now are sensors built-in with individuals actuators to measure attributes these kinds of as strain, temperate, place, airflow, and tilt angle. MEMS and analog circuits dominate these sensors, so they are unlikely to be processed on superior system nodes.

Other improvements are revolutionary, intended to switch functions typically handled by the driver with automated responses in electrical cars. These revolutionary shifts encourage other shifts in fabrication procedures. Between the changes listed here:

- ADAS abilities, which require superior procedure nodes and devices with hundreds of thousands and thousands or billions of transistors

- Wi-fi capabilities, which includes Bluetooth and 5G, and

- Motor vehicle electrification, which increases the usage of discrete electrical power MOSFETS and electrical power administration ICs.

Approximately all new motor vehicles have some advanced chips. In 2018 AAA documented that 92.7% of new autos offered in the United States possessed at the very least one ADAS element. As much more attributes are added with each automation degree, the range of highly developed chips and deals will increase proportionately.

Progressively, that also means automakers will be competing for potential at leading-edge fabs and at specialty fabs. They will be competing with gaming units, computers and sensible telephones, all of which run at substantially larger volume than automotive chips. And they will be competing for specialty fab capacity, which are likely to work at rather very low quantity, applying distinct components. How that will influence excellent and time expended in the fab for numerous testing and inspection, as properly as sufficient ability for production, remains to be witnessed.

Fig. 2: Silicon CMOS capacity for 2021. Supply: IC Insights

Electric power management is a scenario in level. In contrast to CMOS technological know-how for electric power administration equipment, the system technologies have considerably more substantial critical dimensions. STMicroelectronics’ BCD relatives of silicon processes for superior density method nodes ranges from .32µm to .11µm, when for higher voltage BCD the system nodes variety from .32µm to .16 µm. UMC’s BCD technologies nodes vary from .5µm to .11µm. Likewise, RF technologies can variety from 5µm to .11µm method nodes. The technologies also incorporate BiCMOS on SiGe, GaAs, and silicon carbide. Because of to its tolerance of severe environmental disorders, style and design engineers locate silicon carbide equipment desirable, and the devices have apps in both wi-fi and power management modules.

For meeting manufacturing test prerequisites, the variety of integrated solutions in current autos and forecasted for state-of-the-art technologies, there is no one particular dimensions in shape all check demands. Just about every item/method blend will have special issues for test and reliability engineers to equilibrium the charge/yield/high quality triangle. PAT possibly very good plenty of occasionally, but not other people, and now that dividing line is not quite very clear.

Component Ordinary Testing

In automotive IC supplier corporations, products and reliability engineers do use very simple outlier detection take a look at solutions. With PAT engineers, leverage a single parametric measurement and statistical methods to figure out limits. Essentially, even if the DUT passes the information sheet limits, if it is outside your distribution the portion is marked as “fail.” It represents a shift from a specification centered to a defect-centered take a look at system.

Fig. 3: Aspect Regular Tests (reference AEC Q001_rev D). Supply: Anne Meixner/Semiconductor Engineering

The AEC’s PAT guideline provides “a typical approach for taking away abnormal sections and thus boost the excellent and trustworthiness of parts provided for every AEC-Q100 and AEC-Q101… The actual procedures applied may possibly range from what is described in this guideline, especially if distributions are non-standard. These types of derived approaches may well be used with very good statistical justification.”

Engineers determine static PAT limitations based on a affordable sizing of creation materials. Location these kinds of restrictions wants to be accomplished with thorough consideration of the distribution and associated statistical metrics (median vs. imply). So static PAT limitations can be established and programmed in the take a look at application, and an engineer is accomplished. Engineers can utilize static PAT at both of those wafer and closing take a look at.

“Dynamic PAT has the advantage of dynamically placing restrictions based mostly on the general performance of a wafer or great deal,” stated Carl Moore, generate administration expert at yieldHUB. “Often, the distribution on a wafer is considerably tighter than that of a good deal or team of loads. With DPAT, you can established the boundaries dynamically for that wafer distribution and flag outliers from the norm. If you have wider limits to accommodate numerous wafers or loads, then you may perhaps not see an outlier in the larger distribution of several wafers or various ton.”

There are many explanations why merchandise and dependability engineers shift from static to dynamic PAT limitations.

“The IC supplier is motivated to shift to dynamic PAT mainly because static PAT is much too crude of a monitor and expenditures much too substantially produce. The IC shopper drive is the wish for more productive screening and superior quality,” noticed Ken Butler, IEEE fellow and previous take a look at systems architect at Texas Instruments.

Alon Malki, senior director of details science at NI, agrees. “Using outlier detection to decrease field returns is a frequent methodology for at our prospects,” he stated. “So making use of DPAT further optimizes the capacity to detect marginal equipment.”

Easing an engineer’s stress

Yield administration devices (YMS), each within just IDMs and these presented by 3rd-bash knowledge analytic corporations, assist engineers in placing up the algorithm parameters guiding the static and dynamic PAT limit setting.

“A YMS supports engineers by delivering the assessment to simply setup and operate an investigation on their products,” explained Moore. “Basically, the method is working a simulation, and then location the recipe to run in production. At the time established up, the method is automated, and the engineer doesn’t have to shell out time accumulating the data.”

The more historical knowledge offered to engineers, the far more they can recognize the variability in parameters they might choose.

“NI resolution permits engineers to execute substantial-scale statistical evaluation to determine the values desired to suggest/regulate DPAT limits for every exam,” explained Malki. “The outlier detection platform has a simulation capacity more than quite substantial sum of historic information, permitting the engineers to gauge the impact of the chosen configuration.”

Nonetheless, data collection at the tester with older formats impedes the skill for easy application of dynamic PAT. Most engineers creating exam courses use the common records format for parametric measurement in STDF, which success in a ton of inconsistency. Two SEMI benchmarks, TEMS and RITdb, are making progress. When they are comprehensive, they will lighten the information wrangling do the job needed nowadays to get ready information for dynamic PAT.

“For automotive, a good deal of our buyers wished us to directly assistance section common screening, which means just about every check application has to be published with element average screening embedded,” claimed Mark Roos CEO of Roos Instruments. “We demonstrated with RITdb that we can shift the aspect normal testing outside of the tester. Every single shopper has a distinctive definition for portion common testing. RITdb presents the shopper handle about the quality metrics they are making use of and gets the ATE vendor out of their way.”

When PAT fails to provide

These criteria will help, for absolutely sure. But in the spirit of continuous advancement, products and dependability engineers lessen client discipline returns and zero-time examination escapes either by incorporating new tests or generating more use of current parametric test facts.

As the automotive industry adopts much more advanced CMOS procedures they can take benefit of the perform accomplished at these nodes for ASICs and complex processing units. Nevertheless, these rely on using much more than 1 parameter, which provides a new stage of complexity.

“The adoption of semantic knowledge products and improvements in machine studying have made it less complicated for corporations to increase high-quality, effectiveness, and generate by leveraging their massive datasets generated from unique phases of the manufacturing procedure,” claimed Jeff David, vice president of AI Methods at PDF Alternatives. “In the Exensio system, we have used predictive models applying much more than a single variable that can display screen undesirable die superior than standard PAT. Furthermore, we are enabling customers to drive device learning versions out to the edge so that predictions can be made in a much more timely and safe method.”

Continue to, complexity carries on to mature. “Engineering investigation exhibits that specified fail classes are tough to monitor making use of univariate solutions,” reported Butler. “When that transpires, multivariate is the future reasonable stage. The challenge for multivariate is that the number of feasible parameter combinations is large, so which screens do you pick?”

To assist engineers with that option, all companies that present YMS platforms allow engineers to simulate multivariate mixtures with two-dimensional getting the most prevalent. In addition, automotive IC suppliers can use geo-spatial outlier predictive designs to identify latent flaws. At wafer level these are particularly effective prediction techniques.

Bodily inspection also can be ratcheted up noticeably thanks to more rapidly tools and larger precision, which can have a massive impact on coverage. “There are quite a few positive aspects of conducting 100% inspection and metrology,” reported Tim Skunes, vice president of R&D at CyberOptics. “For case in point, there may be cluster problems which could be an indicator of an tools or course of action situation. There could be repeating defects that could most likely reveal a mask/reticle defect.”

The the latest progress of more rapidly optical scan technology has enabled 100% sampling of wafers at crucial layers. This facts can be extra to any YMS platform for assessment of generate reduction problems. Additional importantly, for the automotive sector, this technologies enables detection of latent flaws prior to wafer probe testing. With scans on all wafers, engineers can implement the very same inhabitants statistics to identify maverick die as they have carried out with electrical examination.

“Legacy alternatives for element common testing are built on a basis of electrical exam,” claimed KLA’s Rathert. “It has developed into a multitude of clever variations to recognize and remove at-threat die. But escapes are nevertheless happening due to the fact of latent problems and unavoidable take a look at gaps. KLA’s I-PAT (Inline PAT) resolution delivers a new details stream into the die go/no-go determination, determining outlier die primarily based on production defectivity. Quite a few of these dies will finally fall short exam, but a surprisingly large selection do not — and this has generated a lot of fascination in it as complementary resolution to assist access element-for every-billion escape charges.”

In their 2020 SPIE paper, KLA authors explained the technology: “Each defect is assigned a pounds dependent on its impact to many ‘ground truth’ indicators. The put together influence of all flaws in a offered die stacked throughout all inspections is aggregated into a die-amount metric. Plotting the die-stage I-PAT metrics for all the die as a Pareto chart permits outliers to be discovered applying acknowledged statistical solutions.”

Potential instructions

The mantra of “zero defects” has been echoing for almost two a long time amid semiconductor suppliers to the automotive sector. Still present-day vehicles include things like a various variety of semiconductor systems. They encompass single energy MOSFETs that deal with a power module in an electronic travel educate and neural network processers to appropriate a car’s drift in just a lane.

For univariate outlier detection approaches, static and dynamic PAT will continue being practical for a substantial subset of semiconductor equipment fueling the automotive sector. But responding to subject returns, striving for zero flaws and comprehending dependability mechanisms at some point could travel engineers operating with this subset to gravitate to multi-variant outlier detection techniques.

In the past 15 years, generate administration system developments have decreased the engineering load to carry out PAT. “The modern-day database/analytics platforms can easily estimate dynamic PAT results on a pre-described, or even an on-need foundation,” mentioned Mike McIntyre, director of software program item administration at On to Innovation. “The actuality that a system can be accountable for deciding and implementing the ideal established of restrictions to the proper resources removes a huge duty for the engineer.”

Latent problems remain a challenge for engineers all along the merchandise producing provide chain. Advanced outlier detection techniques already have been applied with some automotive IC products. Advancements in wafer scan engineering assure supplemental abilities.

All solution and high quality engineers enjoy the skill to apply a extra surgical scalpel to discerning which defect will have the most important effect for the shopper. In automotive exactly where margins are often less than strain, the examination technique applied generally arrives down to cost — products, time, generate vs. excellent.

So will PAT ever go absent? “Very number of test techniques ever ‘go absent,’ but they are typically supplemented with newer/much better approaches,” mentioned IEEE’s Butler. “Take, for example, caught-at screening remaining supplemented with changeover tests. There are arguments that mobile-informed technologies might do absent with common stuck-at and changeover tests, but if that takes place, it will just take a very long time. I would have the exact imagined procedure for screening solutions this sort of as PAT. So, I agree that PAT will continue to be utilized indefinitely. But the portion of the production volume to which it is used will be decreasing around time as more refined, economical, and productive techniques are introduced on-line.

Connected

Utilizing Fab Sensors To Minimize Auto Defects

Fab sensing technological know-how coupled with analytics gives a path to boost reliability of autos.

Acquiring Faulty Car Chips (2018)

The road to zero problems requires some new ways.

Automotive Check Moves In-Program

Making certain security-vital units keep on to perform is advanced but vital.

Chips Great Ample To Wager Your Everyday living On

Professionals at the Table: Methods for improving upon automotive semiconductors.